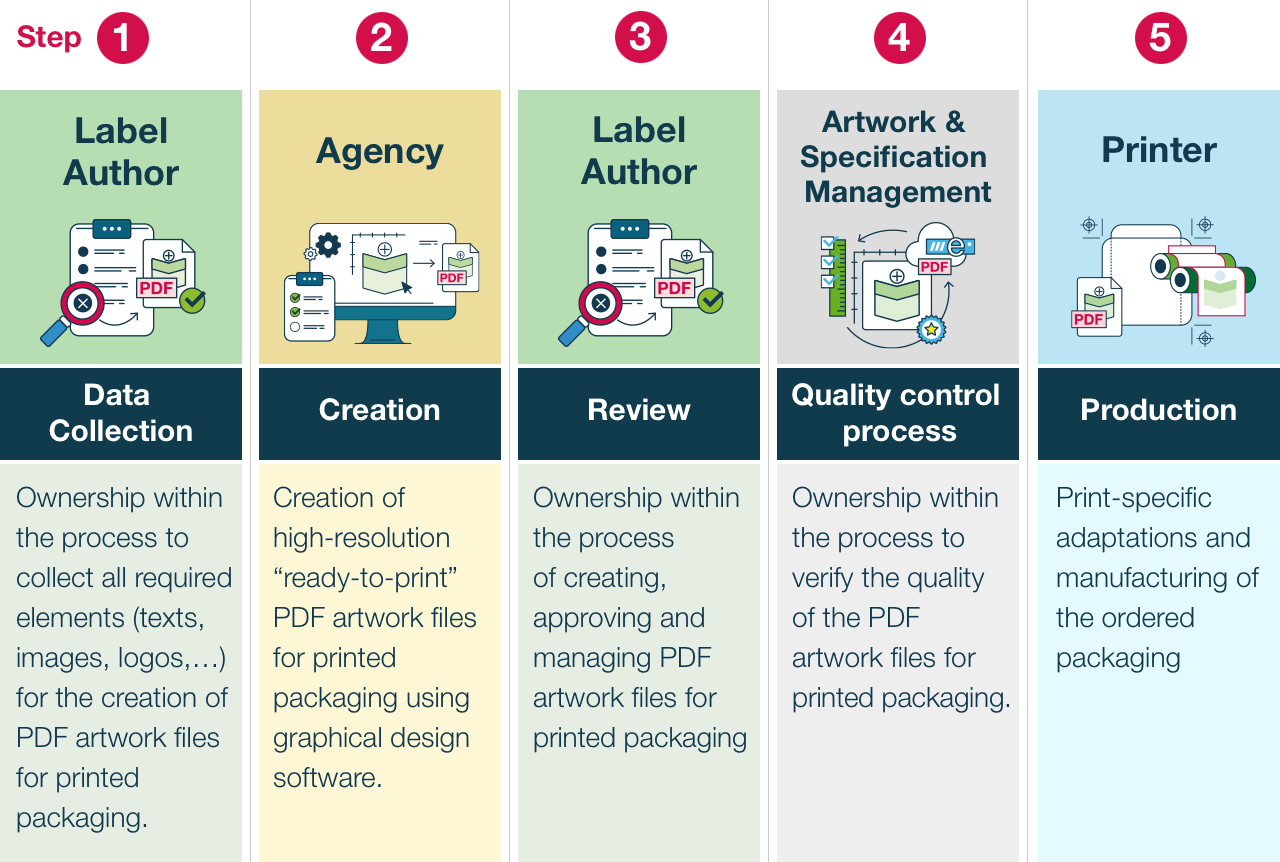

Process Overview

Bayer Crop Science division runs a de-centralized artwork process using global tools, including various process participants.

Artwork creation and approval is always the responsibility of the goods receiving Country Organization (CO) or of our 3rd Party customers. The Artwork & Specification Management (ASM)-team verifies the quality of each PDF artwork file and offers helpdesk functionality for all process participants involved.

Five main steps

The life cycle of an artwork file always contains the following 5 main steps:

1. data collection (text, images, logos, technical drawings,…);

2. creation of a PDF artwork file using graphic software;

3. review / approval process;

4. Quality Control Process - technical PDF quality check;

5. production of the PDF artwork file by a label, foil or bag manufacturer.

If you have any further questions, please contact:

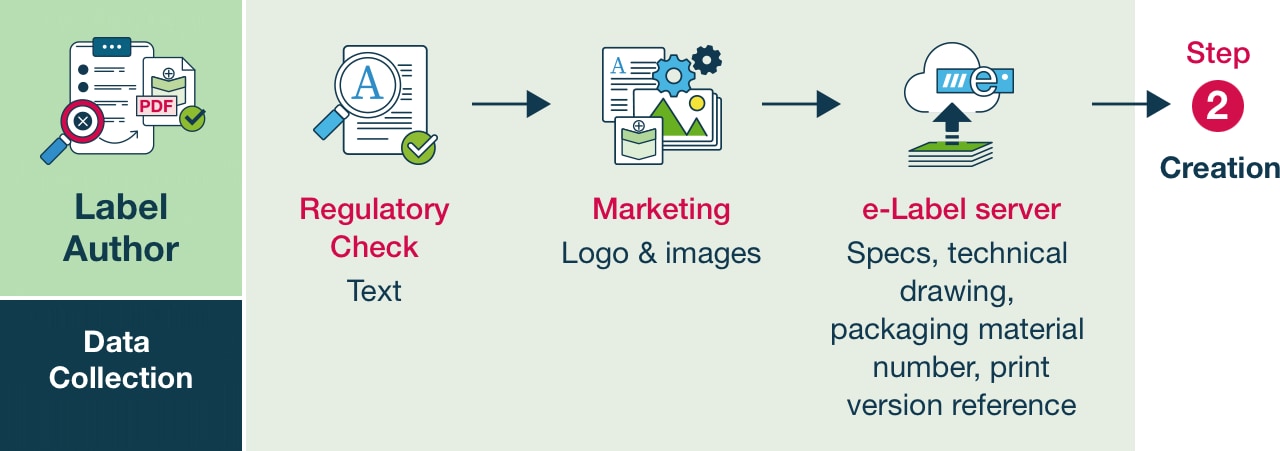

Step 1 · Data Collection

Label Author

Based on receipt of changes to regulatory licenses in a country, the ‘Label Author’ collects all regulatory marketing texts, images and logos of a specific brand.

The e-Label-Server global platform, gives the ‘Label Author’ direct access to the technical drawings of the printed packaging components. These technical drawings are the basis for the creation of the related PDF artwork file. Once all content is available, the ‘Label Author’ either prepares the PDF artwork file internally or issues all content to an external ‘Agency’.

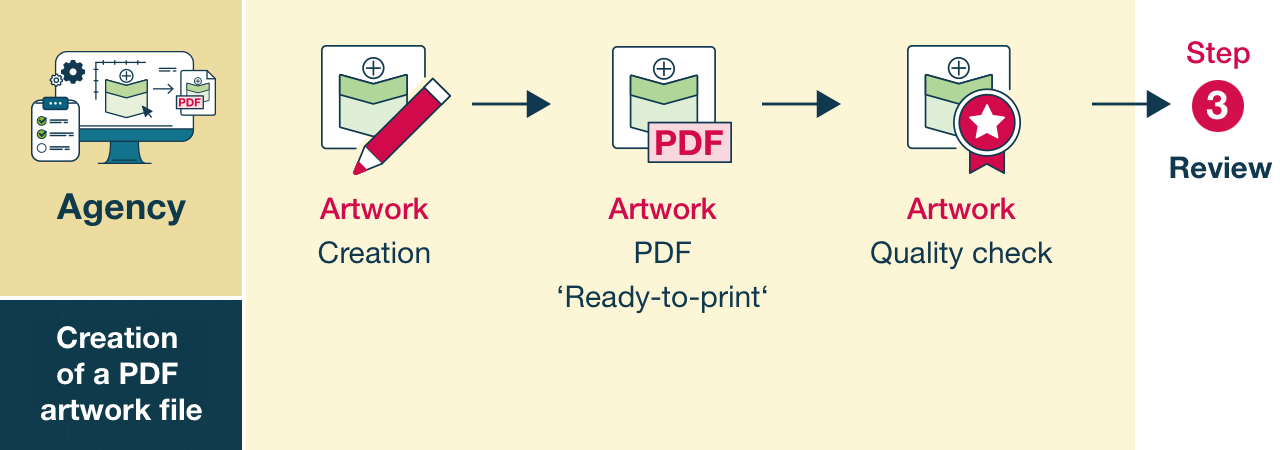

Step 2 · Creation of a PDF artwork file

Agency

An ‘Agency’ uses graphical software (e.g. Adobe InDesign or Illustrator) for artwork creation. During creation of an artwork file, all requirements (e.g. print free areas) as indicated in the technical drawing must be followed.

All content (texts, images, logos,…) as provided by the ‘Label Author’ should be applied. Once the PDF artwork file is ready and the ‘Agency’ processed a completeness check, the ‘Agency’ should perform a technical quality check using Adobe Pre-flight-option with selection of PDF/X-1a:2003.

Only PDF artwork files that fully comply with the terms and conditions of PDF/X-1a:2003 and are fully in line with the requirements as stated in the technical drawing should be send as “ready-to-print” PDF artwork file to the ‘Label Author’.

Step 3 · Review, Approval and Upload of a PDF artwork file

Label Author

The ‘Label Author’ verifies the “ready-to-print” PDF artwork file against Corporate Branding Guidelines and processes a completeness check of both regulatory and marketing requirements.

Depending on the Country Organization and their organizational set-up, the ‘Label Author’ involves additional stakeholders (Marketing, Branding, Regulatory) to review / approve the PDF artwork file.

Only when the PDF artwork file is fully reviewed & approved, it can be launched for upload into the e-Label-Server global platform.

During the upload activity, the ‘Label Author’ can decide how to handle existing stocks (left over from a last production run on a previous version) and indicate until when the new PDF artwork file can be used.

The e-Label-Server global platform is also offering the opportunity for each Country Organization to create /use various individual review and approval workflows. These workflows can include both internal & external stakeholders.

Step 4 · Quality Control Process

Artwork & Specification Management (ASM)-team

Integrated into the e-Label-Server global platform, a complex workflow system - the so-called Switch-workflow – verifies in a semi-automated way the dimensions, coding and printability of each new PDF artwork file.

A file not complying with the terms and conditions of PDF/X-1a:2003 and not fully in line with the requirements as stated in the technical drawing, will be rejected. A detailed explanation on the rejection is provided to the ‘Label Author’.

The ‘Label Author’ prepares a new PDF artwork file based on the details received or shares the details with the ‘Agency’.

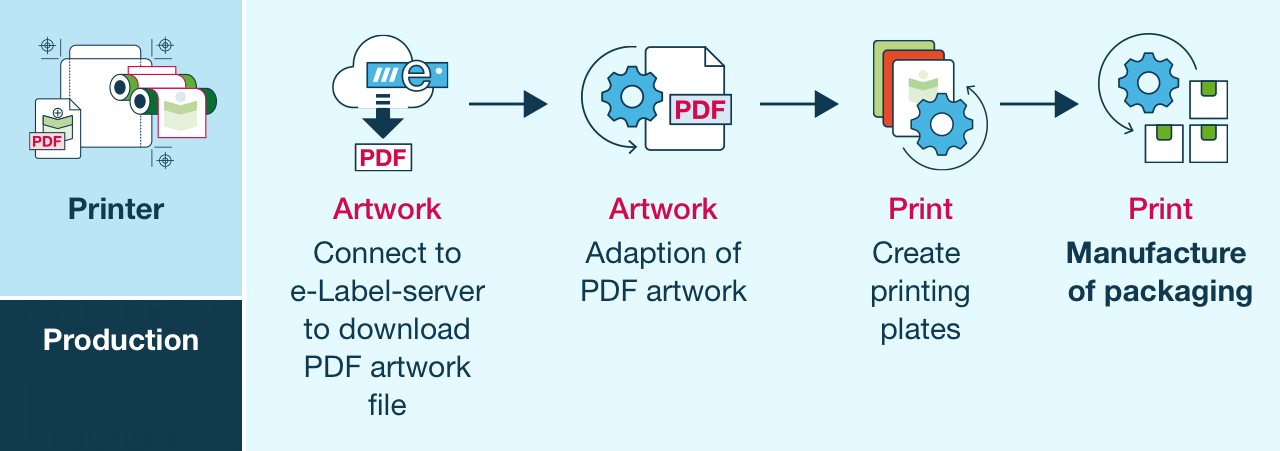

Step 5 · Production

Printer

The printer will download the ‘ready-to-print’ PDF artwork file from the e-Label-Server global platform close to the production run.

As the PDF artwork file is prepared based on an international standard, it is not dedicated to a printing process.

Bayer Crop Science division expects the manufacturer to apply printing process-specific adaptations (e.g. trapping, color conversion for flexo printing,…). However, the manufacturer cannot modify or re-scale the PDF artwork file.

Depending on the setup of the country / region, the manufacturer will issue print proofs close to the manufacturing date of the PDF artwork file.

In some regions (e.g. EMEA / Europe-Africa), print proofs are not required.

When delivering the printed PDF artwork files, the manufacturer should include the so-called ‘Print Version Reference’ into the delivery note.